Hi,

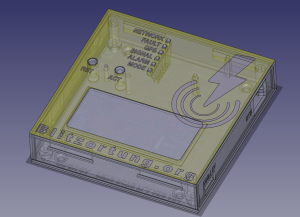

I've also made a housing.

Features:

- Mounting: Bottom part with screw holes or mounting adapter for easy maintenance

- Top lid holding by snappers and easily removable (screws optional)

- Show LED state on top of housing via printed optical fiber

- Holes for the additional LEDs

- Reset and action buttons (printed in place)

- Hole for DFU button

- Text and Logo in different colors

- Transparent "window": Just write station number on it or insert a piece of paper inside the housing for notes etc. (note: not really needed and weakens the lid!)

- < 80g of filament needed, small footprint

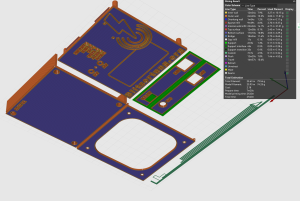

NOTE: I only have a PCB 22.0, which has a slightly different layout (LEDs, Buttons). The files here might work for PCB 22.2, but I can not guarantee!

I developed the model some months ago to learn FreeCAD. Unfortunately I was interrupted by several other things, so maybe I forgot something to mention here... So far I only printed the housing in PETG with my BambuLab X1C for my own station.

Printing notes:

- Print on textured PEI plate.

- Text must lie on bed (adjust/raise nozzle/bed temperatures if text quality is bad)

- Supports are only needed for the panels.

- Text can be colored i.e. by using the fill tool in Bambu Lab.

- The window is optional and can just be printed in the same color as the housing itself if not needed

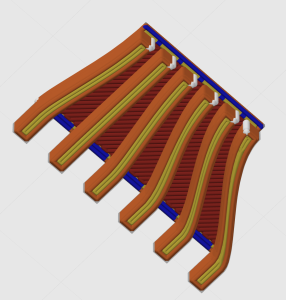

- Optical Fiber must be printed separately with transparent material, the filling must be continuous and must not have any interruptions (see picture)!

The FreeCAD file has several parameters which can be adjusted like wall thickness, height, spacings etc. It should event be possible to adjust it to normal BLUE PCBs. Feel free to test and improve.

Have fun

Tobi