Hi All, After my experience of the last couple of days, I now think that the board is not repairable.

Whilst I have not been able to ascertain exactly what the actual event was I do believe that it might have been preventable!

Whilst accidents do happen in a properly designed product the affects of these are mitigated or held to at least minimum and repairable damage.

I don't think this is the case with PCB 19.c?

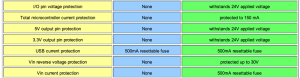

Some ideas about Circuit Protection.

Like this Maybe?

Input protection can be classified into two broad categories. Ones which

protect against software or configuration bugs, or misuse; while the other

protects against exposure to the outside world. We will discuss protection

from software configuration bugs and misuse first.

The three main areas we are interested in are:-

1. Over voltage protection.

2. Over current protection.

3. Over temperature protection.

The first thing anyone who has been around the block a few times will tell you,

is that it is always a good idea to throw a series resistor (Rs) in the path of

any MCU input or not connected leads. This limits the current from the outside world into (or out of)

your MCU. Why does this matter?

A floating input (or output) will produce random and strange results which

might not be easy to debug.

Consider if someone(or you) decides to modify the software which configures

the pin to something other than what was intended? Or if this is allowed to

happen by accident.

Smoke happens.

If that isn't bad enough, consider someone realizes that "pushing" the button

or an instruction would be a bad thing and may cause a short. But they

rationalize to themselves that the push button (for whatever reason) isn't

going to be pressed.

However, what if the pin which is configured as an input, is set (or by

accident is set) to a logical 0. Boom! Out go the lights.

The Software has just created a direct path from Vcc to ground.!

Designs with additional input protections are more difficult to design,

layout and produce, but they can protect you from just about anything.

This is not a cheap kit and these protections are necessary!

Just add them on any future boards and don't rely on LUCK.

It's only a few cents and some space on the PCB. (There is space!)

Usually I don't mind spending a little more of either one for a more

robust design. In this case it should not even be an issue!

Are we using the right input protection?

An important aspect of designs for this environment is interfacing sensitive

electronics with inputs coming from the harsh conditions of real life.

When interfacing digital circuitry with the outside world, care must be taken

to protect the sensitive electronics. However, the circuitry required to

provide the protection is small, inexpensive, and easy to understand.

If a little bit of forethought is used when designing the system, many

difficulties can be avoided once the system is deployed.

Usually, inputs are read by some sort of intelligent processor such as a

microcontroller.

In cases like these, it is imperative to protect the processor from all the

inputs, while still providing a usable signal for the processor to read.

In a typical system there may be several different sensors and a control panel

with the central processing unit. These sensors are connected to central

processing via relatively long wires. Unfortunately this can lead to

inadvertent electronic failure. Long wires can act as an inductor and when a

switch is opened or closed, large voltage spikes can show up on these

electronic paths.

It is not unknown for large voltage spikes to also turn up on power supply

voltages either.

Typical microcontrollers have input impedance on the order of 20 MΩ.

In addition to the normal system voltages ranging from a few milliVolts to

about 5.0 V. it is easy to see the problems with unprotected inputs.

Any large voltage that shows up on any input is presented directly to the

interior electronics (microcontroller). Regardless of how this voltage is

produced (ESD, induced EMI, switch closure, user error), this can damage the

microcontroller, and perhaps cause the entire system to fail.

Because of this, different protection strategies must be implemented to create

a more robust system.

An important aspect of microcontroller inputs (and the vast majority of any

logic ICs) is that they have internal protection diodes that are used to

protect the inputs, these normally forward bias at 0.7 V.

Under ideal circumstances, this can protect the microcontroller.

However, if the voltage is large enough or lasts for a long enough time, it

can destroy the internal diodes in a shorted position, thereby ‘breaking’ the

input pin. Even worse, the input pin is now directly connected to a power rail,

so, when the next large voltage shows up on the input pin, it is shunted

directly to the power bus, wreaking havoc throughout the microcontroller and

most-likely damaging it further.

Even if the diodes are not destroyed, a large ESD spike can induce a current

surge through the microcontroller’s power bus, which can corrupt internal

registers and settings leading to unpredictable behavior.

With all of this in mind, the first attempt to protect these inputs is found

with current limiting

Current limiting

The simplest protection mechanism is a current limiting resistor, the input

resistor is sized so that the voltage drop across it does not affect the

voltage at the microcontroller input. As this is a simple voltage divider, and

the input resistance in the controller is about 20 MΩ, this resistor can be

fairly big. For most digital inputs, a good value is between 100 Ω and 10 kΩ.

For our system, a value of 1 kΩ is used.

This type of protection may work well for short wire connection lengths and

enclosed wire runs (where there is little chance of EMI, etc.).

However, the overshoot or the ringing from the pulse may still exceed the

ratings for a particular system. With the addition of a capacitor, more protection can be added by

turning the simple current limit circuit into a simple low-pass filter.

This type of circuit, can rapidly suppress most spikes, but a little more

thought must be applied to component selection, Because of the frequency

limiting characteristics of the circuit, the value of the resistor and the

capacitor must be sized so that the microcontroller does not miss any signals.

The Equation for determining the resistor and capacitor values in a low pass

filter circuit, of this type, used for a digital input is. (More or less!)

Rise time =2.2RC where the waveform rise time is for the fastest required

incoming leading edge.

To calculate the value of R and C, use the following steps:

Find the fastest edge of the incoming signal – or determine the fastest

frequency of the incoming signal and assume an edge speed of 1/100th of the

input period (a 1 kHz input frequency has an edge of 10 µs).

Select ‘R’. Usually this can be selected to a common value already in the

system, such as 1 kΩ.

Use the equation above to determine the value of ‘C’.

In some cases, the input signal is a very slow moving signal (button press,

switch closure, etc.), so the value of ‘C’ can be then changed to also match a

common value on the board, as long as the order of magnitude is maintained.

One added advantage to the RC filter circuit for a digital inputs is that it

also rejects spurious/fast inputs that could cause false readings on the

microcontroller. Unfortunately, for large ESD events and long wire runs, there

can still be voltage spikes in the microcontroller because the circuit is

relying on the clipping action of the internal diodes. This leads to the next

approach.

External clipping diodes

To assist the use of the microcontroller’s internal diodes, external Schottky

clipping diodes can be used. Schottky diodes are implemented because they

conduct before the internal diodes of the microcontroller (Schottky diodes

forward bias at about 0.2 V as opposed to the 0.7 V of the internal diodes).

Note that a small series resistor is used to protect the Schottky diodes from

overcurrent. As these diodes are only on for a very short time, a small

resistor works well; something on the order of 10 Ω usually works fine.

Alternatively, the 10 Ω resistor can be omitted if the Schottky diodes are

beefy enough to handle short-duration, high current pulses.

So for the most ruggedized digital input protection, a combination of external

resistors, capacitors, and fast diodes should be used.

This should be considered the minimum protection required in any product.

The type of signals that we are trying to capture may make this something off a

design comprimise, but it could be better than it is.

Other ideas

These basic ideas can be further expanded for known higher voltage inputs.

Intentionally or accidently!

For example, if the input signal was changed to switching a high voltage

instead of to ground.

The input clipping diodes to ground are also to protect from less than zero

volt spikes. The damage is often caused by excessive peak to peak wave forms.

The input clipping diodes to just the positive bus is not sensitive enough,

removing or adding the faster Schotky zener diodes after the current limiting

resistor gives better protection.

This also provides a known voltage for the input pin and reduces the amount of

current shunted to the power bus. In addition, all of the connections on the

input are now referenced to ground. Note, in this case, the current limiting

resistor must be sized small enough to provide enough current to allow zener

breakdown at the correct voltage (about 1 mA minimum).

i.e. These small zeners act like a fuse of a smaller rating than the internal

protection diodes of the chip, and being external to the chip are cheaper and

easier to replace in most events.

These techniques will help protect your MCU inputs from bugs in your software,

misuse and and other perils. These techniques should help protect them from

the harsh realities of the outside world which are not always under your

control.

Zener Diode Clamps

Selecting a fast Zener diode with a breakdown voltage slightly higher than the

expected input voltage will help prevent excessive voltage from reaching the

MCU. Again the Zener will prevent voltage exceeding the breakdown voltage by

beginning to conduct it away from the input. A series resistor (Rs) is

required. As an example, a single 5.6V Zener diode such as the 1N4734A can handle 1W

of power dissipation with peaks of 810mA. There are many others all of them

relatively cheap when we consider of factors.

PPTCs

A PPTC is a Polymeric Positive Temperature Coefficient device, used to protect

circuits from excessive current. That's a big long description, but it is more

commonly known as a self-resettable fuse. We all know how a regular filament

fuse works. Too much current and the filament breaks protecting the circuit

from excess current. Later someone replaces the fuse.

With PPTC devices, as the current through the device increases, the temperate

increases until it reaches its switching temperature resulting in a dramatic

non-linear increase in the resistance of the device into the mega-ohm region.

Once the power is removed the device will return to its normal operating state.

If the over-current conditions continues to exist, the process starts again.

PPTC devices exist which can exhibit this behavior milliseconds.

This technology is based on the thermal induced changes in the device material,

so they are also sensitive to changes in ambient temperature.

Typically In normal conditions it acts like a 220-ohm resistor, limiting

current to an input, if the set current is exceeded the device trips.

Devices with higher or lower normal condition resistance also exist.

MOVs

The MOV is a Metal-Oxide Varistor, used to protect circuits from excessive or

transient voltage spikes. Its a voltage dependent, nonlinear device that

provides very good transient voltage suppression. When exposed to high

transient voltage, the metal oxide varistor clamps voltage to a safe level.

A metal oxide varistor absorbs potentially destructive energy and dissipates

it as heat, thus protecting vulnerable circuit components and preventing

system damage.

The Littlefuse V8ZA2P is a 5.5 VDC device used to protect low voltage circuits.

It clamps voltages of up to 20V at a current of 5 amps with peak currents of

250A.

MOVs have been typically used on inputs from household AC line voltage into a

circuit to be protected as a surge protector, but can be used for low voltage

digital inputs as well. The MOV device is connect in between the input signal

and ground.

TVSs

The TVS is a Transient Suppression Diode, used to also protect circuits from

excessive or transient voltage spikes caused from ESD, inductive load switching

and other transient sources. Similar to MOVs you need to consider the maximum

amount of energy the device may need to absorb and the power handing

capabilities of the device while conducting. When a transient voltage occurs,

the TVS clamps instantly to limit the voltage to a safe level and conducts

current away from the circuit being protected. This is called the clamping

voltage (Vc). The operation is similar to a Zener diode, but TVS diodes are

faster acting and are designed to react more quickly to transients.

Zener diodes are designed for slow voltage changes and are more commonly used

in voltage regulators.

Over Temperature sensing devices.

There are many of these rangeing from a simple thermistor to Analog

temperature sensors compatible with small microcontrollers whose output

provides a voltage proportional to the ambient temperature, i.e. they are

temperature controlled voltage regulators.

Simple Common Sense Advice

Many of us are not electronics hobbyists and for many this may even be their

first construction of a kit. While the maounting of the through hole components

is not difficult a few basic pointers will prevent many quite common accidents.

1. Antistatic, ESD protection is essential while working on these boards.

This includes tools, soldering irons and even multimeters, some older types

can have quite high voltage present for measuring resistors and other

components.

2. Antistatic mats and wriststraps should be considered necessary. Some work

surfaces and even your body can generate very high charges.

3. Always switch off the device before making removing any connections, this

means the inter board connetions, the antennas,the router and the PSU.

4. Be particularly careful with probes for test instruments and when handling

the boards when they are working.

5. Never try to solder or change components on a live board, whilst the working

voltages are quite small, transient charges can destroy many sensitive

components.

While this certainly isn't an exhaustive, it should provide some

background and thought before your next design. Next time you have any

external device connected to some circuit input you may want to consider

one or more of these techniques. For further ideas you might look at something like this site:-

https://www.rugged-circuits.com/ruggeduino/

Kindest regards,

Brian.

Whilst I have not been able to ascertain exactly what the actual event was I do believe that it might have been preventable!

Whilst accidents do happen in a properly designed product the affects of these are mitigated or held to at least minimum and repairable damage.

I don't think this is the case with PCB 19.c?

Some ideas about Circuit Protection.

Like this Maybe?

Input protection can be classified into two broad categories. Ones which

protect against software or configuration bugs, or misuse; while the other

protects against exposure to the outside world. We will discuss protection

from software configuration bugs and misuse first.

The three main areas we are interested in are:-

1. Over voltage protection.

2. Over current protection.

3. Over temperature protection.

The first thing anyone who has been around the block a few times will tell you,

is that it is always a good idea to throw a series resistor (Rs) in the path of

any MCU input or not connected leads. This limits the current from the outside world into (or out of)

your MCU. Why does this matter?

A floating input (or output) will produce random and strange results which

might not be easy to debug.

Consider if someone(or you) decides to modify the software which configures

the pin to something other than what was intended? Or if this is allowed to

happen by accident.

Smoke happens.

If that isn't bad enough, consider someone realizes that "pushing" the button

or an instruction would be a bad thing and may cause a short. But they

rationalize to themselves that the push button (for whatever reason) isn't

going to be pressed.

However, what if the pin which is configured as an input, is set (or by

accident is set) to a logical 0. Boom! Out go the lights.

The Software has just created a direct path from Vcc to ground.!

Designs with additional input protections are more difficult to design,

layout and produce, but they can protect you from just about anything.

This is not a cheap kit and these protections are necessary!

Just add them on any future boards and don't rely on LUCK.

It's only a few cents and some space on the PCB. (There is space!)

Usually I don't mind spending a little more of either one for a more

robust design. In this case it should not even be an issue!

Are we using the right input protection?

An important aspect of designs for this environment is interfacing sensitive

electronics with inputs coming from the harsh conditions of real life.

When interfacing digital circuitry with the outside world, care must be taken

to protect the sensitive electronics. However, the circuitry required to

provide the protection is small, inexpensive, and easy to understand.

If a little bit of forethought is used when designing the system, many

difficulties can be avoided once the system is deployed.

Usually, inputs are read by some sort of intelligent processor such as a

microcontroller.

In cases like these, it is imperative to protect the processor from all the

inputs, while still providing a usable signal for the processor to read.

In a typical system there may be several different sensors and a control panel

with the central processing unit. These sensors are connected to central

processing via relatively long wires. Unfortunately this can lead to

inadvertent electronic failure. Long wires can act as an inductor and when a

switch is opened or closed, large voltage spikes can show up on these

electronic paths.

It is not unknown for large voltage spikes to also turn up on power supply

voltages either.

Typical microcontrollers have input impedance on the order of 20 MΩ.

In addition to the normal system voltages ranging from a few milliVolts to

about 5.0 V. it is easy to see the problems with unprotected inputs.

Any large voltage that shows up on any input is presented directly to the

interior electronics (microcontroller). Regardless of how this voltage is

produced (ESD, induced EMI, switch closure, user error), this can damage the

microcontroller, and perhaps cause the entire system to fail.

Because of this, different protection strategies must be implemented to create

a more robust system.

An important aspect of microcontroller inputs (and the vast majority of any

logic ICs) is that they have internal protection diodes that are used to

protect the inputs, these normally forward bias at 0.7 V.

Under ideal circumstances, this can protect the microcontroller.

However, if the voltage is large enough or lasts for a long enough time, it

can destroy the internal diodes in a shorted position, thereby ‘breaking’ the

input pin. Even worse, the input pin is now directly connected to a power rail,

so, when the next large voltage shows up on the input pin, it is shunted

directly to the power bus, wreaking havoc throughout the microcontroller and

most-likely damaging it further.

Even if the diodes are not destroyed, a large ESD spike can induce a current

surge through the microcontroller’s power bus, which can corrupt internal

registers and settings leading to unpredictable behavior.

With all of this in mind, the first attempt to protect these inputs is found

with current limiting

Current limiting

The simplest protection mechanism is a current limiting resistor, the input

resistor is sized so that the voltage drop across it does not affect the

voltage at the microcontroller input. As this is a simple voltage divider, and

the input resistance in the controller is about 20 MΩ, this resistor can be

fairly big. For most digital inputs, a good value is between 100 Ω and 10 kΩ.

For our system, a value of 1 kΩ is used.

This type of protection may work well for short wire connection lengths and

enclosed wire runs (where there is little chance of EMI, etc.).

However, the overshoot or the ringing from the pulse may still exceed the

ratings for a particular system. With the addition of a capacitor, more protection can be added by

turning the simple current limit circuit into a simple low-pass filter.

This type of circuit, can rapidly suppress most spikes, but a little more

thought must be applied to component selection, Because of the frequency

limiting characteristics of the circuit, the value of the resistor and the

capacitor must be sized so that the microcontroller does not miss any signals.

The Equation for determining the resistor and capacitor values in a low pass

filter circuit, of this type, used for a digital input is. (More or less!)

Rise time =2.2RC where the waveform rise time is for the fastest required

incoming leading edge.

To calculate the value of R and C, use the following steps:

Find the fastest edge of the incoming signal – or determine the fastest

frequency of the incoming signal and assume an edge speed of 1/100th of the

input period (a 1 kHz input frequency has an edge of 10 µs).

Select ‘R’. Usually this can be selected to a common value already in the

system, such as 1 kΩ.

Use the equation above to determine the value of ‘C’.

In some cases, the input signal is a very slow moving signal (button press,

switch closure, etc.), so the value of ‘C’ can be then changed to also match a

common value on the board, as long as the order of magnitude is maintained.

One added advantage to the RC filter circuit for a digital inputs is that it

also rejects spurious/fast inputs that could cause false readings on the

microcontroller. Unfortunately, for large ESD events and long wire runs, there

can still be voltage spikes in the microcontroller because the circuit is

relying on the clipping action of the internal diodes. This leads to the next

approach.

External clipping diodes

To assist the use of the microcontroller’s internal diodes, external Schottky

clipping diodes can be used. Schottky diodes are implemented because they

conduct before the internal diodes of the microcontroller (Schottky diodes

forward bias at about 0.2 V as opposed to the 0.7 V of the internal diodes).

Note that a small series resistor is used to protect the Schottky diodes from

overcurrent. As these diodes are only on for a very short time, a small

resistor works well; something on the order of 10 Ω usually works fine.

Alternatively, the 10 Ω resistor can be omitted if the Schottky diodes are

beefy enough to handle short-duration, high current pulses.

So for the most ruggedized digital input protection, a combination of external

resistors, capacitors, and fast diodes should be used.

This should be considered the minimum protection required in any product.

The type of signals that we are trying to capture may make this something off a

design comprimise, but it could be better than it is.

Other ideas

These basic ideas can be further expanded for known higher voltage inputs.

Intentionally or accidently!

For example, if the input signal was changed to switching a high voltage

instead of to ground.

The input clipping diodes to ground are also to protect from less than zero

volt spikes. The damage is often caused by excessive peak to peak wave forms.

The input clipping diodes to just the positive bus is not sensitive enough,

removing or adding the faster Schotky zener diodes after the current limiting

resistor gives better protection.

This also provides a known voltage for the input pin and reduces the amount of

current shunted to the power bus. In addition, all of the connections on the

input are now referenced to ground. Note, in this case, the current limiting

resistor must be sized small enough to provide enough current to allow zener

breakdown at the correct voltage (about 1 mA minimum).

i.e. These small zeners act like a fuse of a smaller rating than the internal

protection diodes of the chip, and being external to the chip are cheaper and

easier to replace in most events.

These techniques will help protect your MCU inputs from bugs in your software,

misuse and and other perils. These techniques should help protect them from

the harsh realities of the outside world which are not always under your

control.

Zener Diode Clamps

Selecting a fast Zener diode with a breakdown voltage slightly higher than the

expected input voltage will help prevent excessive voltage from reaching the

MCU. Again the Zener will prevent voltage exceeding the breakdown voltage by

beginning to conduct it away from the input. A series resistor (Rs) is

required. As an example, a single 5.6V Zener diode such as the 1N4734A can handle 1W

of power dissipation with peaks of 810mA. There are many others all of them

relatively cheap when we consider of factors.

PPTCs

A PPTC is a Polymeric Positive Temperature Coefficient device, used to protect

circuits from excessive current. That's a big long description, but it is more

commonly known as a self-resettable fuse. We all know how a regular filament

fuse works. Too much current and the filament breaks protecting the circuit

from excess current. Later someone replaces the fuse.

With PPTC devices, as the current through the device increases, the temperate

increases until it reaches its switching temperature resulting in a dramatic

non-linear increase in the resistance of the device into the mega-ohm region.

Once the power is removed the device will return to its normal operating state.

If the over-current conditions continues to exist, the process starts again.

PPTC devices exist which can exhibit this behavior milliseconds.

This technology is based on the thermal induced changes in the device material,

so they are also sensitive to changes in ambient temperature.

Typically In normal conditions it acts like a 220-ohm resistor, limiting

current to an input, if the set current is exceeded the device trips.

Devices with higher or lower normal condition resistance also exist.

MOVs

The MOV is a Metal-Oxide Varistor, used to protect circuits from excessive or

transient voltage spikes. Its a voltage dependent, nonlinear device that

provides very good transient voltage suppression. When exposed to high

transient voltage, the metal oxide varistor clamps voltage to a safe level.

A metal oxide varistor absorbs potentially destructive energy and dissipates

it as heat, thus protecting vulnerable circuit components and preventing

system damage.

The Littlefuse V8ZA2P is a 5.5 VDC device used to protect low voltage circuits.

It clamps voltages of up to 20V at a current of 5 amps with peak currents of

250A.

MOVs have been typically used on inputs from household AC line voltage into a

circuit to be protected as a surge protector, but can be used for low voltage

digital inputs as well. The MOV device is connect in between the input signal

and ground.

TVSs

The TVS is a Transient Suppression Diode, used to also protect circuits from

excessive or transient voltage spikes caused from ESD, inductive load switching

and other transient sources. Similar to MOVs you need to consider the maximum

amount of energy the device may need to absorb and the power handing

capabilities of the device while conducting. When a transient voltage occurs,

the TVS clamps instantly to limit the voltage to a safe level and conducts

current away from the circuit being protected. This is called the clamping

voltage (Vc). The operation is similar to a Zener diode, but TVS diodes are

faster acting and are designed to react more quickly to transients.

Zener diodes are designed for slow voltage changes and are more commonly used

in voltage regulators.

Over Temperature sensing devices.

There are many of these rangeing from a simple thermistor to Analog

temperature sensors compatible with small microcontrollers whose output

provides a voltage proportional to the ambient temperature, i.e. they are

temperature controlled voltage regulators.

Simple Common Sense Advice

Many of us are not electronics hobbyists and for many this may even be their

first construction of a kit. While the maounting of the through hole components

is not difficult a few basic pointers will prevent many quite common accidents.

1. Antistatic, ESD protection is essential while working on these boards.

This includes tools, soldering irons and even multimeters, some older types

can have quite high voltage present for measuring resistors and other

components.

2. Antistatic mats and wriststraps should be considered necessary. Some work

surfaces and even your body can generate very high charges.

3. Always switch off the device before making removing any connections, this

means the inter board connetions, the antennas,the router and the PSU.

4. Be particularly careful with probes for test instruments and when handling

the boards when they are working.

5. Never try to solder or change components on a live board, whilst the working

voltages are quite small, transient charges can destroy many sensitive

components.

While this certainly isn't an exhaustive, it should provide some

background and thought before your next design. Next time you have any

external device connected to some circuit input you may want to consider

one or more of these techniques. For further ideas you might look at something like this site:-

https://www.rugged-circuits.com/ruggeduino/

Kindest regards,

Brian.